Manual of GPJ-(04)6 fiber optic splice closure

Applications

The product can be applied in the straight line and branch line (one into two, one into three) connections of optical cables within the diameter of 16mm(φ), all types and structures, when laid overhead, in the pipeline, underground or in the well. Meanwhile, it is also applied to the connection of all-plastic city phone cables.

Features

● All property indexes are in accordance with National YD/T814-2013 Standard.

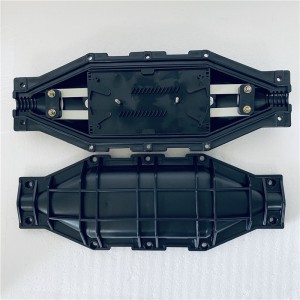

● The case body is made from imported high-intensity engineering plastics(ABS) and formed the shape with mould plastics under high pressure. It is in the shape of HALF rectangle, with the advantages of less weight, high mechanical intensity, corrosive-resistance, anti-thunderstruck and long service life.

● The case body and cable entrance are sealed with adhesive rubber strip(non-vulcanized) and sealed tape. Reliable sealing capability. It can be re-opened and easy to maintain.

● Overlapping fiber-melting tray and separate insulation earth unit make the disposition of the cores, expanding the capacity and cable-earthen flexible, convenient and safe.

● Outer metal component and fixing unit are made of stainless steel, so can be repeatedly used in different environments.

Specification

● External Size: (length×width×height) 390 × 140×75

● Weight: 1.2kg

● Optical fiber winding radius: ≥40mm

● Extra loss of fiber tray: ≤0.01dB

● Fiber length left in tray: ≥1.6m

● Iber capacity: single: 48core

● Working temperature: - 40℃ ~ + 70℃

● Lateral pressure-resistance: ≥2000N / 10cm

● Shock-resistance: ≥20N.m

Operations

● Choose the cable loop with proper outer diameter and let it go through the optical cable. Peel the cable, take off the outer and inner housing, as well as loose contract tube, and wash off the filling grease, leaving 1.1~1.6mfiber and 30~50mm steel core.

● Fix the cable pressing card and cable, together with cable reinforce steel core. If the diameter of the cable is less than 10mm, first bind the cable fixing point with adhesive tape till the diameter has reached 12mm, then fix it.

● Lead the fiber into the melting and connecting tray, fix heat contract tube and heat melt tube to one of the connecting fiber. After melting and connecting the fiber, move heat contract tube and heat melt tube and fix the stainless (or quartz)reinforce core stick, make sure the connecting point is in the middle of the housing pipe. Heat the pipe to make the two into one. Put the protected joint into the fiber-laying tray. (one tray can lay 12 cores).

● Lay the left fiber in the melting and connecting tray evenly, and fix the winding fiber with nylon ties. Use the trays from the bottom up. After all the fiber has been connected, cover the top layer and fix it.

● Position it and use the earth wire in accordance with the project plan.

● Sealing the cable retainer nearing the inlet of splice closure and the joint of the cable rings with sealing tape. And close the unused inlets with plugs, with exposed concave parts of the plug sealed with tapes. Then put sealing trips into the sealing groove on the sides of the shell and grease the concave part of inlet of the body between the two parts of the shell. Then close the two parts of the shell and tighten it with stainless steel bolts. The bolts should be screwed tightly with balanced force.

● According to the laying requirement, position and fix the hanging tool.

Packing list

● Joint case main body: 1set

● Block: 2 pcs

● Seal tape: 1 coin

● Seal stick: 2 pcs

● Earthing wire: 1 stick

● Abrasive cloth: 1 stick

● Labeling paper: 1 piece

● Stainless steel nut: 10 sets

● Heat shrinkable sleeve: 2-48 pcs

● Hitcher: 1 piece

● Nylon tie: 4-16 stick