Metal Spinning Part

-

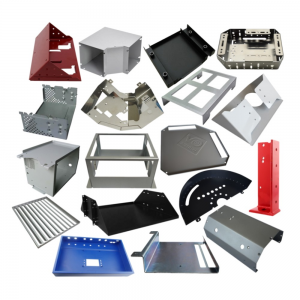

OEM Factory CNC lathe machine Parts custom cnc machining set service cnc lathe machine parts

Looking for a reliable, quick-turn supplier of machined plastic and metal components? With hundreds of CNC machines, the unmatched capacity of our in-house digital factories ensure your parts are shipped on-time, every single time. At Protolabs, our CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components. But through our digital network of manufacturers at HTLL, you can unlock advanced machining capabilities like tighter tolerances, volume pricing, and anodizing. We’re your single supplier of machined parts with manufacturing tailored to your project needs.

-

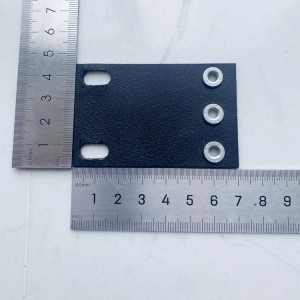

23” to 19”1U/2U/5U Fiber optic Rack reducer brackets

23′ to 19”1U/2U/5U Fiber optic Rack reducer brackets

Shipping Method:Small Package (UPS)

The RB-1U converts your 23 or 24 inch wide rack to support 1u of EIA 19 inch wide rackmount equipment. Made of 16-gauge steel and sold in pairs, these reducer brackets feature universal square hole mounting providing you the ultimate flexibility for your rack.

We also accpet OEM service. any metal parts can be produce

-

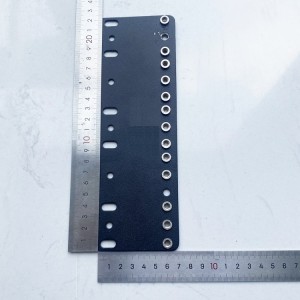

5U 23″ to 19″ Rack Reducer

A simple solution for 23″ rack.

How do you install a standard 19” rack equipment in to a 23” relay rack or 23” 4 post cabinet? The answer is simple. You need a RCB1060 series 23” to 19” RACK Reducer. RCB1060 gives you the 2” extension you need for right side and left of your cabinet to fill the gap.

What is a RACK REDUCER ?

RCB1060 PEM Nut 23” to 19” rack reducer is a special 2” wide bracket design for mounting 19” rack equipment in a 23” cabinet. You need two brackets for right and left side of your cabinet to properly install your 19” rack equipment.

Save Money and save enviroment.

If you own a 23” telecom relay rack or 23” 4 post cabinet, you can reuse and repurpose a section for 19” rack application. Your 23” telecom cabinet offers the exact same features as a standard 19” rack cabinet except for the width. By using our RCB1060 PEM nut rack reducer, instead of paying full price for a brand new 19” rack, you only pay fraction of cost for a pair of RCB1060 rack reducer. You are not only saving money, you are also saving the environment by reusing resource. RCB1060 offer size from 1U up to 5U to choose from

-

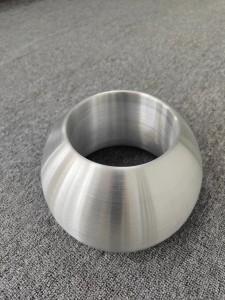

OEM Sheet Metal Spinning Processing

Metal spinning, also known as spin forming or spinning, is a metalworking process that involves rotating a metal disc or tube on a lathe while applying pressure with a tool to shape it into a desired form. The process is commonly used to create cylindrical or conical shapes such as bowls, vases, and lampshades, as well as complex geometries like hemispheres and paraboloids.

During metal spinning, the metal disc or tube is clamped onto a lathe and rotated at high speed. A tool, called a spinner, is then pressed against the metal, causing it to flow and take on the shape of the tool. The spinner can be either hand-held or mounted on the lathe. The process is repeated multiple times, with the shape gradually refined with each pass until the final form is achieved.

Metal spinning can be performed using a wide range of metals, including aluminum, copper, brass, stainless steel, and titanium. It is commonly used in the manufacturing of components for the aerospace, automotive, and lighting industries, as well as for decorative and artistic purposes.